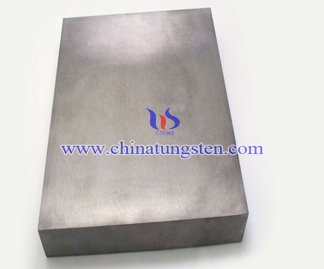

Tungsten Carbide Tank Armor Plates

Tungsten carbide tank armor plates using powder metallurgy process and mixing by ball milling, pressing and sintering processes made with high wear resistance, high hardness (89HRA), high bending strength and chemical stability, but also because of its non-toxic, in order to reduce the materials used in the military field on the harm to the environment, for the production of tank armor pieces.Tungsten carbide tank armor plates under high temperature conditions, maintaining good flexibility and mechanical strength, due to cobalt or nickel powder binder phase powder made with high strength and toughness.

Carbide has high hardness, strength, wear resistance and corrosion resistance, known as the "industrial teeth", used in the manufacture of cutting tools, cutting tools, cobalt tools and wear parts, widely used in military, aerospace , field machining, metallurgy, oil drilling, mining tools, electronic communications, construction, etc., with the development of downstream industries, carbide market demand is increasing continuously. And the future of high-tech weaponry and equipment manufacturing, as well as the rapid development of cutting-edge advances in science and technology, nuclear energy, will greatly increase demand for high-tech and high stability of carbide products. Carbide has been widely used, its main purpose is to manufacture high performance, high proportion of non-toxic weapons and controllable power behavior. Due to the high hardness and high temperature alloy, it has been increasingly used in the military field.