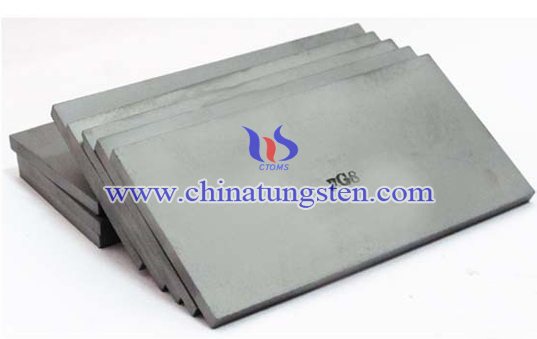

Non Magnetic Tungsten Carbide Plates

Non-magnetic energy of non magnetic tungsten carbide plates is excellent , can be used to magnetic field for mold press forming, corrosion-resistant tools .It has high hardness and high wear resistance, good bending strength, impact toughness and chemical inertness, technology (machining, forging and heat treatment) is strong, not easily deformed. Mainly for the powder molding and sintering. Classified by repression can be divided into two kinds of ordinary isostatic pressing and. General suppression of upper / lower die right pressure, two-way pressing, isostatic products for six surface while pressing, isostatic pressing of sheet metal carbide products, density, uniform pressure, can reduce the porosity and trachoma. By sintering to distinguish, can be divided into: general sintering and sintering overvoltage, overvoltage sintering mostly thick, can reduce the stress of cemented carbide.

Non-magnetic carbide that are not magnetic or weakly magnetic carbide materials. Continue to the final product, but depending on the amount of residual chlorine and form different, and has a degree of difference. Using non-magnetic carbide, tungsten organizations and phase composition of steel with different cooling conditions to produce some of the changes, the use of this feature of tungsten steel heat treatment can improve their physical and mechanical properties, its excellent performance instead of the non-magnetic You can exponentially increase the work efficiency.